Beverage & Dairy

On-Site Generated Electrolyzed Water

& Water Treatment

& Water Treatment

- SANITATION

- WATER PURIFICATION

- WATER DISINFECTION

Electrolyzed Oxidizing Water is an all natural and environmentally friendly sanitizer that can replace toxic chemicals being used for beverage & dairy plant sanitation.

Electrolyzed Oxidizing Water can control the growth of bacteria and biofilm on manufacturing tools and equipment. It can also be used to sanitize cans and bottles used for manufacturing beverages.

Electrolyzed Oxidizing Water can dislodge and eradicate microbial pathogens that form bioflim from within the interior surfaces of pipes, vessels, process equipment, and filters without disassembly.

Electrolyzed Oxidizing Water is safe and non-irritant and can be used to help sanitize hands and feet prior to entering a facility.

Electrolyzed Oxidizing Water can be used to sanitize floors and contact surfaces of a facility by direct application, pressure spraying, or fogging.

On-Site and On-Demand

EcoloxTech systems are compact and easy to install. Systems are designed to generate Electrolyzed Oxidizing Water on-site and on-demand from an additive made yourself with just table salt and water.

What is Electrolyzed Oxidizing Water?

Electrolyzed Oxidizing Water is electrolytically generated hypochlorous acid (HOCl), a neutral-to-acidic electrolyzed water. HOCl has been studied for over 100 years and it is an undeniable fact that it is a more powerful oxidant than chlorine bleach. Only within the last 30 years have we been able to generate solutions of near 100% HOCl in such a stable form. HOCl kills bacteria, bacterial spores, and viruses 100 times more effectively than chlorine bleach.

How does it work?

Electrolyzed Oxidizing Water is a powerful oxidant (800 to 1000 mV) that can kill microbial pathogens immediately upon contact by damaging cell walls or inactivate the pathogen by entering and disrupting proteins, lipids, and DNA.

Has it been researched?

In the last 30 years we have collected over 300 published research articles supporting the use of Electrolyzed Oxidizing Water. Nearly every common bacterial pathogen has been studied such as E. coli, Salmonella, Listeria, Vibrio, Staphylococcus, MRSA, spore forming bacteria, and many common viruses (including Norovirus) and fungi. To learn more please visit our research page and search by microbe or industry to find applicable research.

What about regulation from FDA, USDA, and EPA?

We have pages dedicated to the regulation of electrolyzed water as it pertains to the FDA, USDA, and EPA. Please visit our pages for more information. In regards to healthcare sanitation, see our page for the CDC.

Beverage & Dairy Plant Sanitation

Electrolyzed Oxidizing Water (EOW) can replace toxic concentrated chemicals being used for beverage and dairy plant sanitation. EOW is not only safe but highly effective against microbial pathogens that cause foodborne illness. EOW has been shown in repeated studies to reduce and inactivate Salmonella, Listeria, and E. coli. EOW is also effective against hard to kill sporeforming bacteria such as Clostridium and Bacillus. EOW has many applications within a facility from hand sanitation, to cleaning and sanitizing contact surfaces, tools, equipment, bottles, and CIP systems.

CIP Systems

CIP systems can be degreased and sanitizied in a two step process using Eco-Friendly Cleaner & Degreaser (alkaline electrolyzed water) followed by EcoloxTech Cleaner & Sanitizer (neutral-to-acidic electrolyzed water).

Freshly generated EOW is a mixed oxidant solution primarily composed of hypochlorous acid but also of other powerful oxidants such as ozone and chlorine dioxide. These mixed oxidants, when injected directly into CIP systems, are highly effective at dislodging and eradicating biofilm from within pipes, vessels, process equipment, and filters.

Pressure Spraying and Fogging

When cleaning and sanitizing contact surfaces, tools, equipment, or large rooms, EOW can be appied by pressure sprayers or fogging. As long as the electrolyzed water (hypochlorous acid) makes contact with the microbial pathogens in liquid form, it is effective as an antimicrobial.

Inactivating Microbial Pathogens

Research has consistently demonstrated that electrolytically generated hypochlorous acid is effective at inactivating the major foodborne pathogens:

- Clostridium perfringens

- Campylobacter spp.

- E. coli (O157)

- Listeria monocytogenes

- Norovirus

- Salmonella

- Staphylococcus aureus

- Toxoplasma gondii

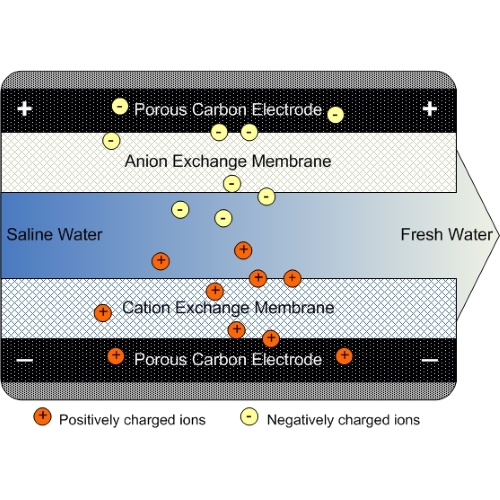

CDI effectively removes most inorganic contaminants that are charged species such as nitrates, ammonia, arsenic, lead, flouride, magnesium, calcium, and total dissolved solids (TDS) or salinity.

CDI can also remove organic contaminants if they have a charge. However, most organic contaminants can be removed by activated carbon filters prior to running through the CDI.

CDI can remove radionuclide contaminants such as alpha particles, beta particles, Radium, and Uranium.

EcoloxTech Water Purification

EcoloxTech builds water purification systems using membrane capacitive deionization (CDI) technology.

How much water can it purify?

EcoloxTech CDI systems can be stacked with any number of CDI cells to meet the need of any project small or large. Whether it be for a home, business, manufacturing plant, or municipality, EcoloxTech can custom build a CDI system specific to any application.

How does it work?

CDI is a technology to purify water by applying an electrical potential difference over two porous carbon electrodes. Anions (negative charge) are removed from the water and are stored in the positively polarized electrode. Likewise, cations (positive charge) are stored in the cathode, which is the negatively polarized electrode.

Removing Contaminants

CDI is able to effectively remove the following water contaminants:

- Temporary Hardness: Ca , Mg

- Total Hardness: CaCl2 , MgCl2 , CaSo4 , MgSO4

- Total Dissolved Solids (TDS)

- Chlorides and Sulphates

- Sodium chloride: NaCl

- Sodium Sulphate: Na2SO4

- Nitrate Anion NO3

- Nitrite Anion NO2

- Ammonia NH4+

- Iron (Fe) (when present in ionic form)

- Magnesium (Mm) (when present in ionic form)

- High level of oxidizers (when connected with humic acid)

- Organic Micro pollutant (when present in dissociated form)

- Hexavalent chrome

- Arsenic

- Fluorides

- Heavy Metals

EcoloxTech CDI systems can be designed, engineered, and custom built to meet the needs of almost any application. The percentage of demineralization can be varied based on the specific water needs. This can be done by varying the potential difference across the electrodes from 1 to 1.6V. This characteristic, unique in respect to all other water purification technologies in the industry, allows for the alteration of the water’s taste.

CDI Advantages

EcoloxTech CDI has many advantages over Reverse Osmosis (RO):

- Minimal Water Wasted – Compared to conventional RO systems that waste more than 30% of the water, the maximum water wasted in EcoloxTech CDI systems is less than 10%. This results in long-term conservation of ground water.

- Lower Operating Cost – EcoloxTech CDI systems use no chemicals and have lower consumable requirements for operation. The systems consume less power and the total cost of producing treated water is in the range of 1 cent per 10 liters

- Simplistic Operation – EcoloxTech CDI systems have a built in controller that automates the working of the system in local conditions and the entire system can be managed with little or no training.

- Small Footprint – A typical EcoloxTech CDI system requires very little space to operate. EcoloxTech can build systems for homes that are small enough for a countertop or systems large enought to meet the needs of municipalities.

- Environmentally Friendly – Since EcoloxTech CDI systems do not use any chemicals for treatment, the water drained from the system does not contain any chemicals that are hazardous to the environment. This ensures the safe release of water back to the environment.

- Retention of Beneficial Minerals – Unlike water treatment in a typical Reverse Osmosis system, where most of the minerals are removed from the incoming water, EcoloxTech CDI systems can be set to retain desired levels of minerals that are beneficial to the human body.

EcoloxTech Electrolyzers can disinfect all the water needed for food and beverage manufacturing without using toxic concentrated chemicals.

EcoloxTech electrolyzers are eco-friendly and can disinfect water for beverage manufacturers at a fraction of the cost.

EcoloxTech electrolyzers generate a powerful mixed oxidant solution that inactivate microbial pathogens by damaging their cell walls and disrupting their internal proteins, lipids, and DNA.

Sales/Quote Inquiries:

contact@ecoloxtechasian.com +84 909 169 889EcoloxTech Water Disinfection

The EcoloxTech 1200 Electrolyzer can disinfect water on-site and on-demand from just salt, water, and electricity.

How much water can it disinfect?

Each system can generate enough free available chlorine in the form of hypochlorous acid to disinfect 200 Liters of water per minute. The systems can be stacked to disinfect any volume of water

How does it work?

The EcoloxTech 1200 Electrolyzer generates a mixed oxidant solution primarily composed of hypochlorous acid (HOCl) but also other powerful oxidants such as ozone and chlorine dioxide. Hypochlorous acid is a powerful oxidant that is stable in solution that can kill microbial pathogens immediately upon contact by damaging cell walls and disrupting internal proteins, lipids, and DNA.

Has it been researched?

In the last 30 years we have collected over 300 published research articles supporting the use of Electrolyzed Oxidizing Water for disinfection. Nearly every common bacteria has been studied as well as viruses and fungi. To learn more please visit our research page and search by microbe to find applicable research.

What about EPA regulation?

Because electrolytically generated hypochlorous acid is a free chlorine molecule, it falls under the Safe Water Drinking Act (42 U.S.C. 300f et seq. 1974) which allows for a free chlorine concentration of up to 4 ppm.

Inactivating Microbial Contaminants

Water disinfection by electrochemical activation is not only more effective than conventional methods of water disinfection, but it is less expensive and environmentally friendly.

The conventional methods, which have seen extensive use over the last 100 years, include chlorine gas and chlorine solutions of sodium hypochlorite (bleach). Despite the vast amount of experience gained over the years, these methods have disadvantages, including the cost of the chemicals and the large investment required for protection and safety equipment.

Electrolyzed water composed of mixed oxidants and hypochlorous acid is 100 times more effective than sodium hypochlorite yet requires no protective gear or safety equipment and is non-toxic, non-irritant, and eco-friendly.

EcoloxTech electrolyzers eliminate the need for purchasing, transporting, storing, and preparing of toxic concentrated chemicals and can meet all the water disinfection needs of the ship by on-site generation. Food and Beverage Plants can switch to an environmentally friendly technology while saving time, space, and money.

Electrolytically generated hypochlorous acid eliminates common microbial contaminants:

- Adenovirus

- Caliciviruses (including Norovirus)

- Campylobacter jejuni

- Enterovirus (including polioviruses, coxsakieviruses, and echoviruses)

- Escherichia coli (O157)

- Helicobacter pylori

- Hepatitis A

- Legionella pneumophilia

- Mycobacterium avium

- Salmonella enterica

- Shigella sonnei